-

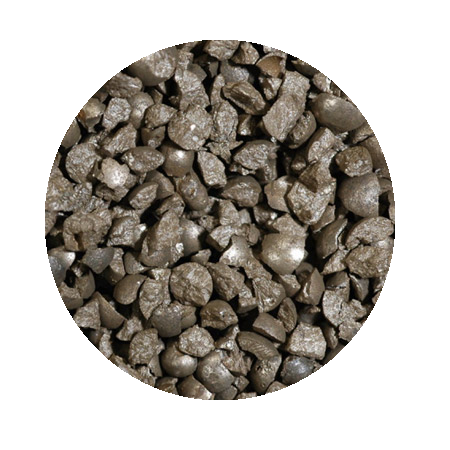

Cast Iron Grits / Chilled Iron Grits

All Abrasives Industries offer high quality Cast Iron Grits / Chilled Iron Grits that are manufactured by melting cast iron followed by atomisation and grain crushing. Because of extreme hardness, the grains disintegrate into sharp-edged particles during the blasting process, giving rise to grits. These grits then become perfect with high cleaning and roughening properties.

Our Cast Iron Grits / Chilled Iron Grits are angular in shape and feature a white texture, with a carbon content in excess of 1.7% and up to 3.5%, and hardness above 750 HV/63RC.

Our Cast Iron Grits / Chilled Iron Grits are best suited to meet the requirements of a variety of customers who need tough and fast cleaning media that produce a sharp and angular profile for use in compressed air powered blast rooms and booths. Our iron grits are perfectly sharp, angular, hard and brittle. They are also reusable, which makes them highly cost-effective.

Cast Iron Grits / Chilled Iron Grits are ideal for air blast applications requiring an aggressive cutting rate. They are ideally suited for surface preparation prior to the application of metal spray coatings. All Abrasives Industries’ Chilled Iron Grits can also be used as high-density aggregates in ballast applications and for radiation shielding.

-

Below are some of the salient features of this product:

⋅ They are widely used in castings for sand removal, air blast applications, removing of old paints, cleaning of castings and metallurgical materials, blasting and cutting of stone, and cleaning in foundries.

⋅ They are also used to etch structural steel and components before coating with paint, metal spray & plastics.

⋅ They offer quicker cleaning action and much better quality compared to garnet.

⋅ They are also used in surface preparation for electroplating, enamelling, and painting, shot-blast cleaning of castings, forgings, rolled steel (before and after heat treatment).

⋅ It is angular in shape and used for surface preparation by handguns in open having hardness HRC 62±.

Chemical Composition of Cast Iron Grits:

-

C

2.8 – 3.4 %

Mn

0.6 – 1.0%

Si

0.8 – 1.20 %

P

0.15 – 0.45

S

0.25 – 0.50

Hardness

700-800 HV / 63.5 HRC or above

Micro Structure

White Iron Structure

Density

> 7.0 kg/l (Approx)